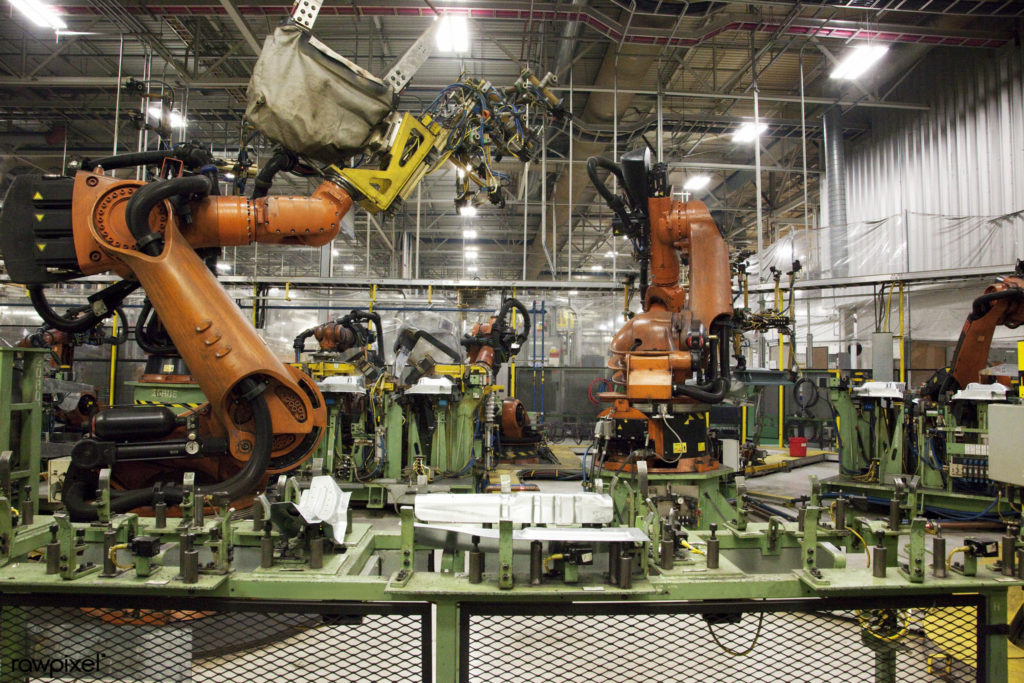

Cost of Inaction – Is Your Manufacturing Shop floor Hemorrhaging or Leveraging?

by Eileen SullivanScully on 12th March 2018

Cost of Inaction – Is Your Manufacturing Shop floor Hemorrhaging or Leveraging?

The cost of inaction has some real dollars attached to it. In this article, I’d like to explain some of the real costs involved in deploying a cloud based electronic system on the shopfloor. It starts with asking the top level, middle management and shopfloor engineers one simple question: Are you coping or deploying?

Many pharma/biotech manufacturing sites are coping with their current paper processes on the shop floor. C-Levels avoid or delay technology upgrades like electronic logbooks and paper on glass systems. Some try and use an existing homegrown system or use a legacy system that is outdated, bulky and costs a lot of money to maintain.

Worse yet is expecting their already time stressed operations, quality and IT managers to scope out a project and write their own system. Since when can these highly trained manufacturing operators, quality assurance and IT people have the skill set to formulate user requirement documents, write, deploy and maintain an electronic system? These manufacturing people are close to losing their minds with frustration at their old legacy system, homegrown internal solution and the mounting issues around the inefficient paper system. Surprising? Not really. This scenario is all too common in pharma/biotech manufacturing.

Shopfloor managers struggle with massive amounts of paper logs, forms and spreadsheets that they manually stitch together and share using emails, re-keying of data and posting on display boards. Inefficient processes that occur from using outdated bulky systems or “homegrown” systems result in decreased profit margins because of lost time reviewing paper documents and costly maintenance of the existing system. Workers do not have a clear understanding of the project scope. How could they? They are managing spreadsheets and trying to resolve inefficiencies from the shift before. Other issues arise like the time it takes to locate the batch record or fix the deviation. The fact is your manufacturing site is hemorrhaging money and valuable resources not leveraging assets.

What EIS has found is usually the delay is rooted in fear of a past software implementation from a bulky, expensive, outdated legacy system. Remember legacy systems are expensive, cause a lot of disruption and are expensive to maintain. This fear causes the organizations Stakeholders to hesitate and avoid implementing an electronic system. In their minds they remember the problems and the money. All too often staying compliant and competitive gets pushed back and the cost of inaction sets it.

It doesn’t have to be this way. The cost of inaction has real dollars attached to it. There are soft costs and real costs. I have tried to outline some of the real costs associated with inaction. The hope is that organizations can realize what it is costing their manufacturing shopfloor and act now. Since there are soft costs and real costs, many organizations may not be aware of all the costs of inaction. Here are some of the costs involved with inaction.

Soft Costs:

- Avoiding data errors when writing it in from one log or spreadsheet to the next.

- Avoiding costs because of lack of visibility and rectifying issues from the shift before.

- Avoiding costs by departments working in silos and lack of collaboration. This often happens because teams don’t have the critical tools to share workflows, quality issues, data and documents.

Cost of Quality:

In critical manufacturing plants would you use tools you’d find in a test kitchen making chocolate chip cookies? Of course not! Then why would a high level manufacturing site use common tools like MS Office to manage their data? The quality and consistency of shopfloor reporting data being used is critical to make key decisions. The ability to deliver what your website and marketing materials say is dependent on more than the capability of your staff. They need the right tools. Electronic logbooks and forms or paper on glass batch records solutions, like OpsTrakker, perform at the level of quality you expect from pharma and biotech manufacturing.

What gets missed?

What about those costs? Pigs don’t know pigs stink aka you don’t know what you don’t know. Relying on chunk data from paper spreadsheets, printed paper forms and searching for documents in emails it’s not a matter of what, it’s a matter of when. Key deliverables are going to get missed and there’s a sense of flying under the radar that leads to quality related costs. These are big dollars especially if the FDA starts to scrutinize your operations and paper records. It’s not a secret anymore that the FDA does not like the paper systems. They’re not the only ones. Younger workers like the Gen X and Millennials don’t like the paper and aging Baby Boomers can’t deal with the paper anymore either.

New Opportunity:

Productivity is vital for new opportunities. If your staff is manually building reports, chasing data, and spending a lot of time doing tedious manual work, frustration sets in. Remember these folks are highly trained engineers, project managers, experts etc. their sense of satisfaction is very low. There is no value or satisfaction here. Deploying new opportunities gets met with resistance because the staff doesn’t have the right tools (electronic system) to reconcile all the pieces of critical information on the shopfloor. It’s near impossible to have good outcomes.

Competition:

Trouble keeping up with competitors is a real cost because we are a global economy. Competitors are already using electronic solutions like e-logbooks and paper on glass batch records have the edge. Using new technologies like OpsTrakker improves operator usage. This makes systems easy to deploy, intuitive, faster and fun to use. Don’t let your biggest customer ditch you (it happens all the time) because you’re still using paper systems on the manufacturing shopfloor.

Take Action. Standing still means your manufacturing site is getting left behind.

The conclusion is there’s plenty of new opportunities for everyone, but manufacturing has to take action. The cloud, IoT, SaaS and many technologies leverage the power of connectivity to create better, faster and more efficient manufacturing sites. These technologies, like OpsTrakker electronic logbooks and paper on glass MES, pay for themselves quickly. Unlike the old, bulky, legacy systems of the past, manufacturing sites can realize return on investment quite quickly because the cost of a system like OpsTrakker may be less than maintaining the existing system.

The game changer here is that freeing up manufacturing workers time to do other more important things brings real value to the company. Speeding up time from product lifecycles to market means manufacturing companies can no longer afford using outdated systems and paper.

Your customers could become your greatest enemies on social media due to disruptions and issues related to recalls and warning letters by the FDA. Rather than leaving your company to chance and risk, embrace modern technology in your manufacturing shopfloor now. Inaction and procrastination aren’t options anymore. Immediate change (not eventual) into an electronic system like Opstrakker or paper on glass allows for higher productivity gains, higher returns and happy manufacturing workers.